Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India, Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia, Venezuela, Peru....

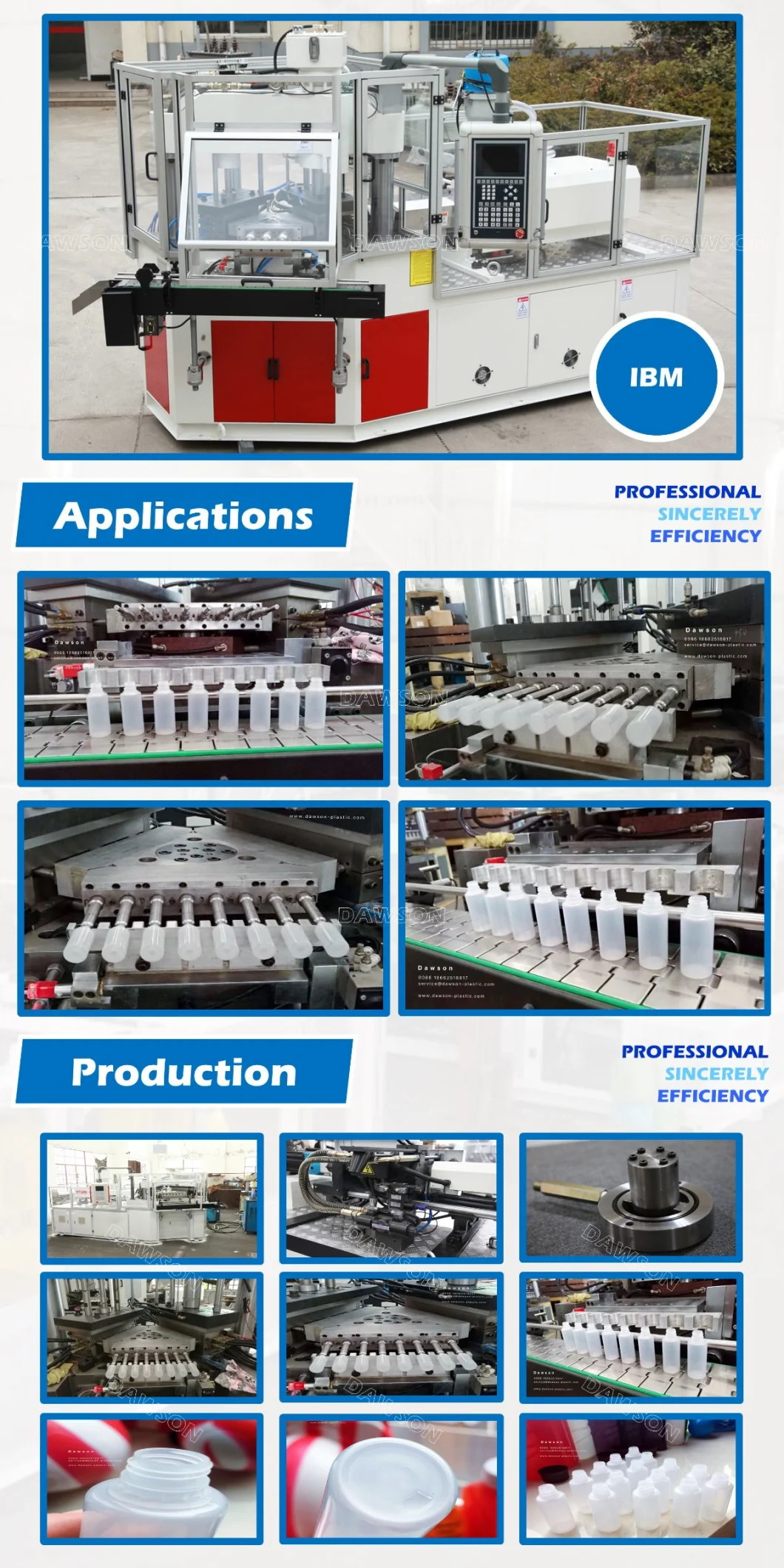

Injection Blow Molding Machine IBM35D

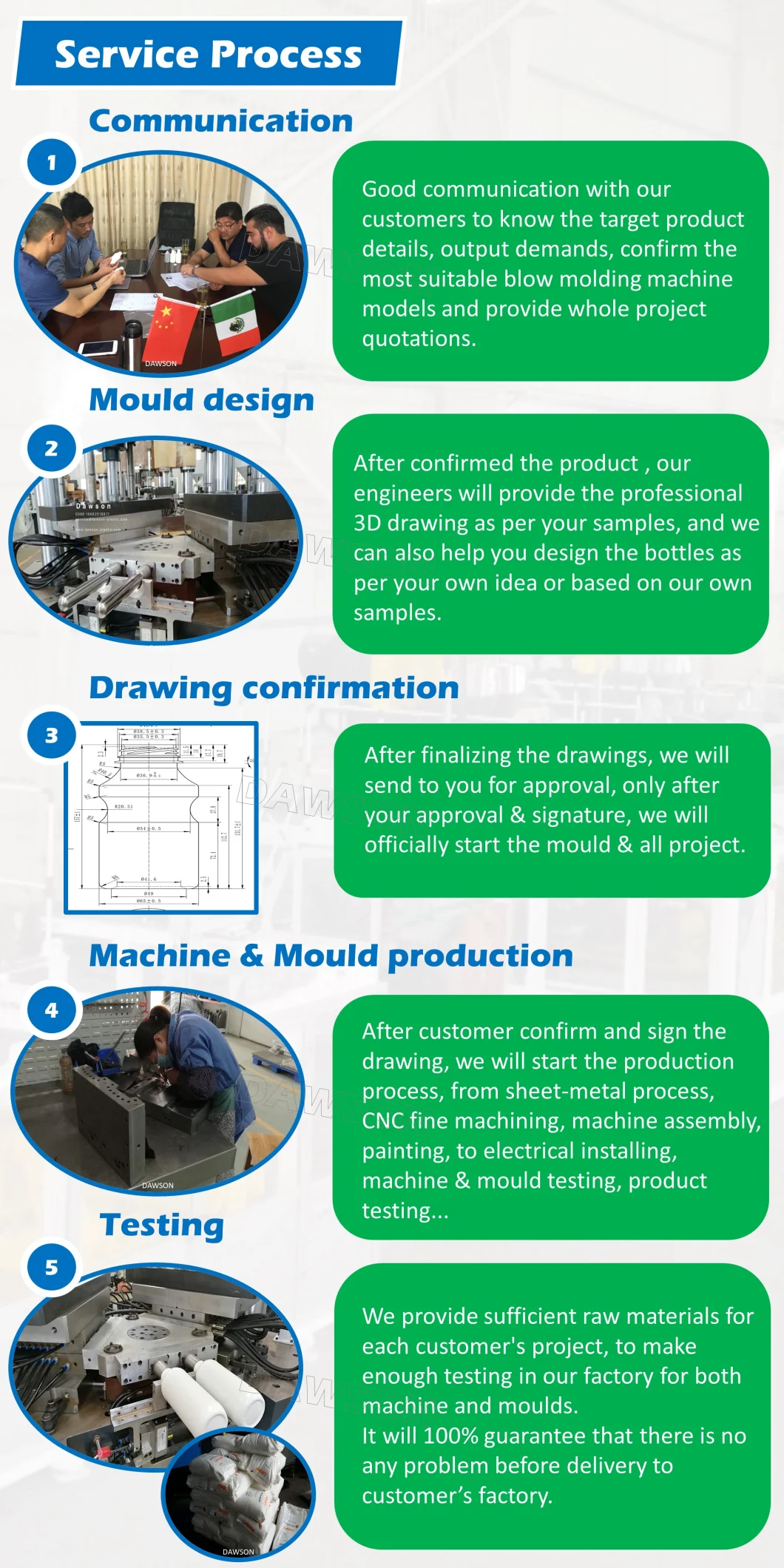

| Item | Unit | Date | |

| Injection system | Screw Diameter | mm | 40 |

| Max. Theoretical injection capacity | G | 176 | |

| Heating capacity | KW | 7.2 | |

| No. of heating area | Qty | 3 | |

| Clamping & blowing system | Clamping force of injection | kn | 350 |

| Clamping force of blowing | kn | 40 | |

| Opening stroke of mold platen | mm | 120 | |

| Max. Platen size (L×W) | mm | 420×340 | |

| Min. Mold thickness (H) | mm | 180 | |

| Heating capacity of mould | KW | 2.8 | |

| Product dimension range | Suitable bottle range | ml | 3-800 |

| Max. bottle height | mm | ≤180 | |

| Max. Dia. of bottle | mm | ≤80 | |

| Dry cycle | s | 4 | |

| Hydraulic driving system | Motor power | KW | 11/15 |

| hydraulic pressure | Mpa | 14 | |

| Pneumatic system | Min. Air pressure | Mpa | ≥0.8 |

| Discharge rate of compressed air | M3/mm | ≥0.7 | |

| Cooling system | Water flowage | M3/h | 3 |

| Total rated power with mold heating | KW | 21/25 | |

| Machine information | Dimension | M | 3.1×1.2×2.2 |

| machine weight | Ton | 4.0 |

* Excellent plasticizing unit

* Bridge clamping unit for synchronism mould open/close, cycle time less

* Servo system can save 35 to 40% energy compared to normal system

* Servo rotary, precise, long using time, easy maintenance, save energy.

* Optional injection with all-electric way, replacing hydraulic way * CE certificate

Configuration of Injection Blow Molding Machine

* Oil pump and hydraulic valve (Directional Valves, Power saving valves, Pilot operated check modular valves, and Throttle check modular valves): YUKEN brand Ex JAPAN.

* Pneumatic valve connector: FESTO Ex Germany.

* Oil seal: VALQUA brand Ex JAPAN.

* Controlling system: Act Technologies

* Electronic Rulers: Italy GEFRAN

* Molded case circuit breaker, contactor, Thermal overload relay: SCHEIDER brand Ex FRANCE.