JASU FACTORY ONE STEP INJECTION STRETCH BLOW MOLDING MACHINE ISB 1100N-3

.1. The whole process including mold injection, stretch blowing and off-molding can be finished within one step, which means more energy efficiency and high quality for product.

The injection blowing molding products are thinner and better uniformity than old style ones, which can save 50% materials. Meanwhile, hygienic requirements is guaranteed.

2. Compact structure cover small floor coverage, which can save more cost than traditional machines.

3. Widely used for manufacturing bottles for pharmaceutical, healthcare, food, beverages, cosmetic, lampshade and other applications.

4. Can use recycling material with the lowest cost.

JASU one step blow machines include

Injection blow molding machine and injection stretch blow molding machine.

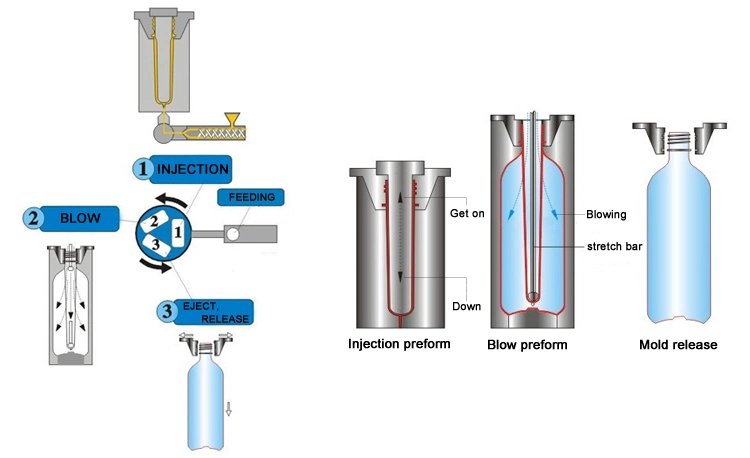

The machines are three stations, injection preform, blow/stretch blow and product release. The raw material comes from the hopper to the injection

screw to inject preform; the plate rotates preforms to blow/stretch blow station with themselves heat, without any reheating for blowing,

Then the product will rotate to release station and drop down, it is fully automatically cycle rotation working mode.

JASU One Step Injection Stretch Blow Molding Machine advantages are as follows:

1. The wheel rotation is driven by electrical servo motor, not hydraulic.

2. Full automatic controlling system, easy operating

3. The temperature of material barrel and hot runner is controlled accurately by PIT.

4. More cost is saved than traditional machine.

5. Compact structure; less space needed

6. Injection: Hot runner and temperature control device are standard configuration. Only change mold for making a new product; Stretch Blow:

Hydraulic mold clamping, core insert, stretch blow and bottom molding are standard configuration;Product Release:Equipped with a standard ejector.

| ISB 800N-3 Main Specification | Main Devices Brand | ||

| Material | PC,PP,PET,TRITAN,PCTG, PETG, PMMA,PS | Servo Motor and Oil Pump | Phase (Italy) and Eckerle (Germany) |

| Screw Diameter | 40mm | Sealing Parts | SealTech, China |

| Screw L/D Ratio | 20.5:1 | Hydraulic Valve | Yuken(Japan), TAIWAN |

| Screw Speed | 0-190 | Air Valve | AirTAC |

| Theoretical Injection cavity | 238cm3 | Air Cylinder | AirTAC |

| Injection Pressure | 174Mp | Controller (PC) | JASU, TAIWAN |

| Max.hydraulic Pressure | 140kg/cm | Low-voltage components | Joint Venture |

| The actual injection quantity | 225g(ps),8Oz | F.R.L | China |

| Screw Stroke | 190mm | Servo Motor for Turntable | Inovance,China |

| Blow Clamping Force | 150kn | Gear Reducer | SESAME, Taiwan |

| Clamp Tonnage | 600kn | ||

| Wheel Diameter | 1100mm | ||

| Max.Height Of Bottle | 220mm | ||

| Open Vertical Mode Trip | 570mm | ||

| Max.Pump Pressure | 16Mpa | ||

| Servo Motor | 22kw | ||

| Double pump | 22kw | ||

| Electric power | 8.9kw | ||

| Tank volume | 450L | ||

| Dimension of Machine | 4.5*1.95*3.6m | ||

| Machine Weight | 8T | ||

For PC, PS,PMMA, SAN lamp cover, LED light lampshade,Christmas flash light, garden and street light.

For PET , PETG high transparent,much thinner wall, cosmetic bottle , PET wide neck jar, PET pharmaceutical bottle

For PP high transparent, baby feeding bottle, sport bottle

For PCTG, Tritan drinking water bottle, sport bottle.

Mould and tooling, we have mould workshop ourselves, advanced CNC machine and smart design engineers,we can treat different material and size products from different customers over the world.

Auxiliary machine,we will equip you with the necessary quality auxiliary machines to ensure the production plan running well,we can supply you one-stop service.

JASU group

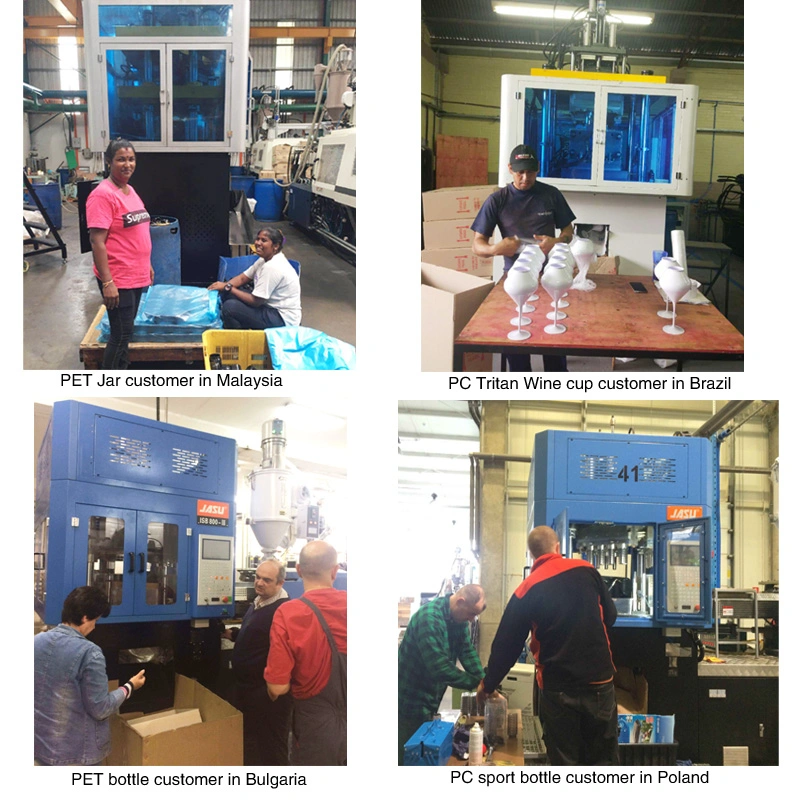

Gauangzhou Jasu Precision Machinery Co.Ltd is a sabusidiary of JASU International Machinery Group locates in Guangzhou China, which is top 3 supplier of CNC machine tools in South China. JASU owns R&D center and factories in Guangzhou. JASU has been dedicated to manufacturing machine for 20 years. Absorbing the design and manufacture of Taiwan and Germany, JASU create a series of highly distinctive, automatic and cost-effective one step Injection (Stretch) Blow Molding Machine. JASU has got high reputation and trust among customers by means of modern management method, perfect quality, novel design and reasonable price.

Your specialist consultant

Monica

FAQ:

Q1: All of your products are made by yourself or compacted via purchasing from others?

A1: JASU have independent technical team who focus on making machines and moulds, all the products are made by our technical team.

Q2: What is the ability of your factory?

A2: About injection stretch blow molding machine, we can product more than 30 sets machine per month

Q3: Do you have any technical supports about your products?

A3: We have had long term collaboration with German, and we have a lot of cooperation with a lot of advanced manufacture company on the world.

Q4: Do you have any other service about your products?

A4: We have a lot of experience on making complete "Turn-Key" projects and specifications for our clients. Also we have a fixed service system

Pre-Sales Service

* Inquiry and consulting support.

* Free product design.

* Visit our Factory.

Warranty

* The machine and mold guarantee for one year with repair/ free replacement of defective parts.

* Spare parts of machine components, mold components and tools are shipped along with the machine.

After-Sales Service

* JASU wants to make sure you are getting the very best out of the machine and mold. After delivery, we will send our engineer to your plant to train your staff how to use the machine well, until we get approval by the customer.

* Remote assistance to help you solve problems in case of machine system failure.

Q5: The route to JASU factory

A5: A: Our factory near Line 3 Shiqiao suway station A exist

B: It takes about 15 minutes from Guangzhou South Railway Station to our factory

C: It takes about 50 minutes from Guangzhou airport to our factory