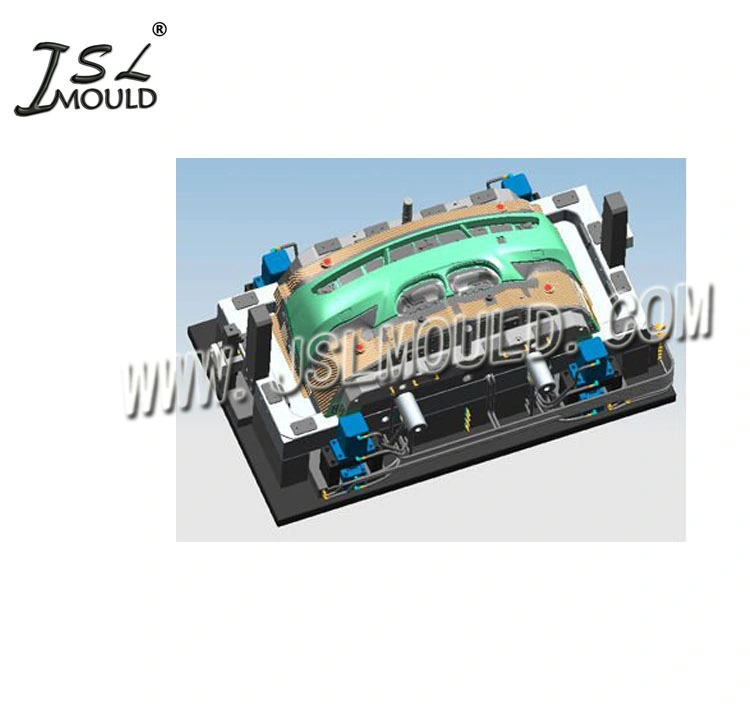

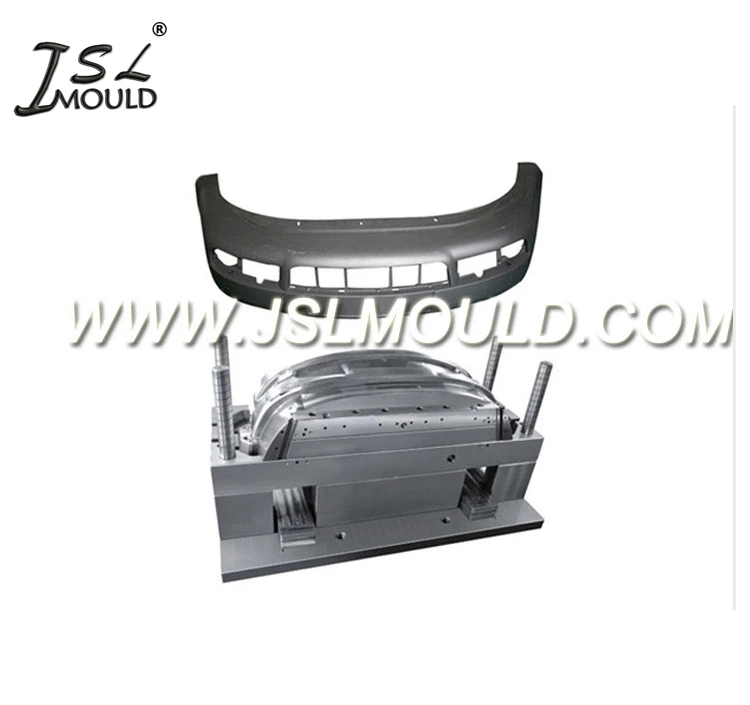

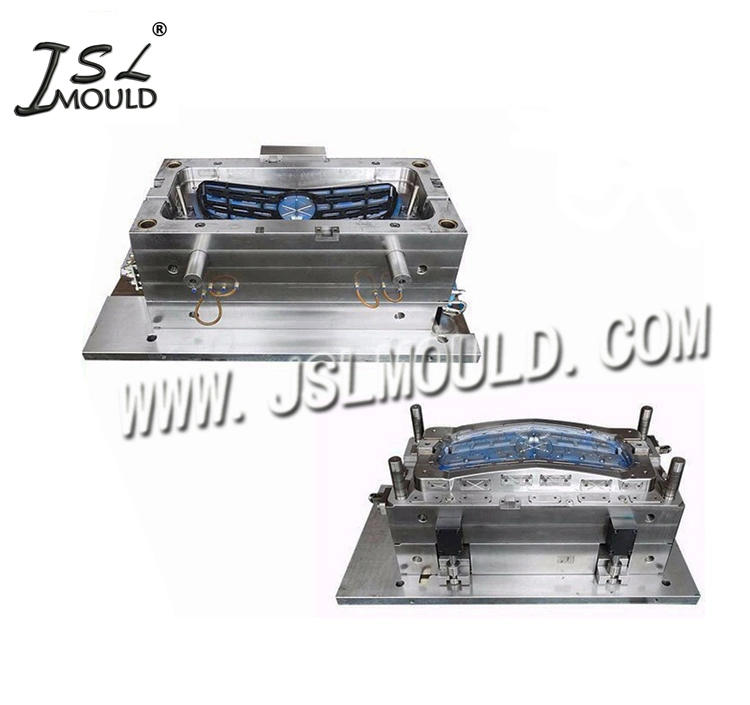

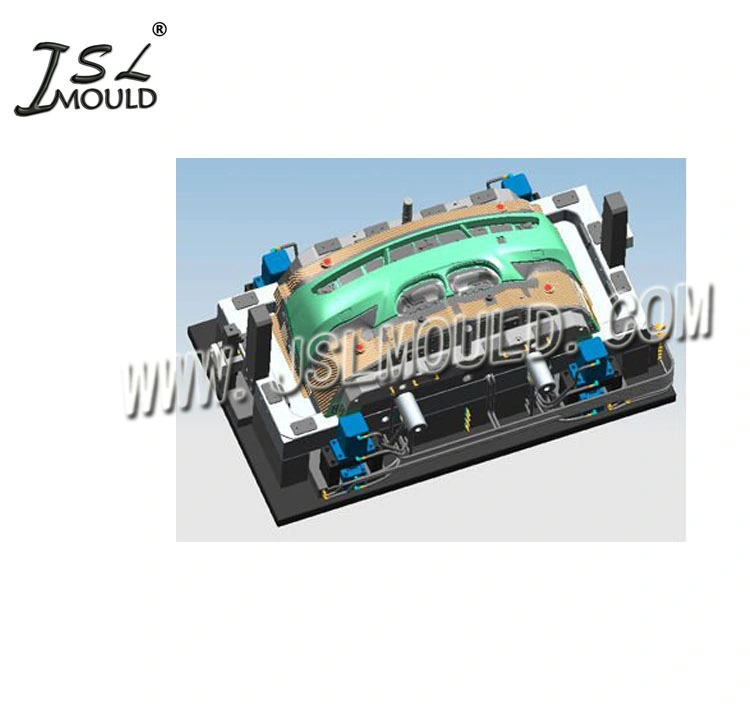

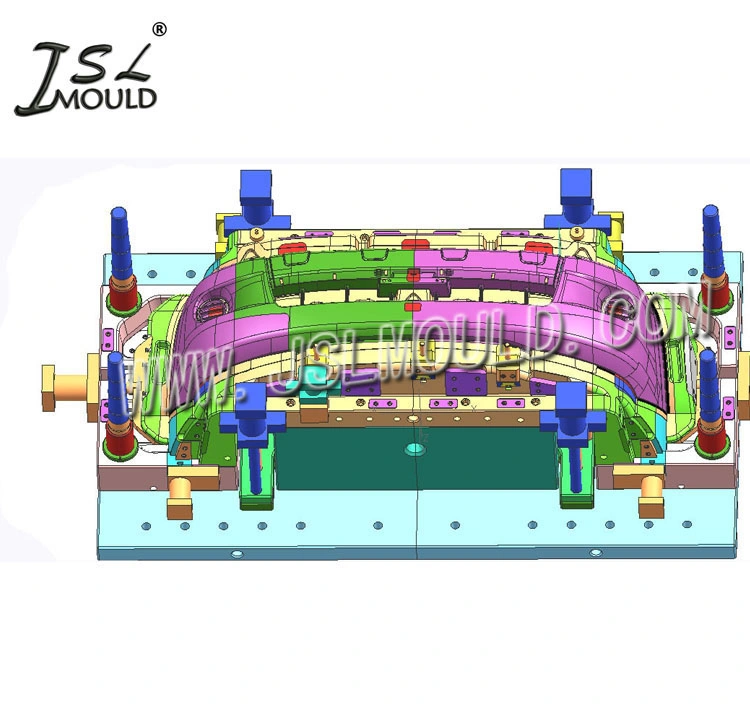

Professional Making High Quality Plastic Car Bumper mold

1. Provide 3D design

2. Mould Steel/hardness:718

3. OEM service

4. Mould life: 5 000, 000shotsJSL Mould Quality Control

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking(Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Making Process Q/C

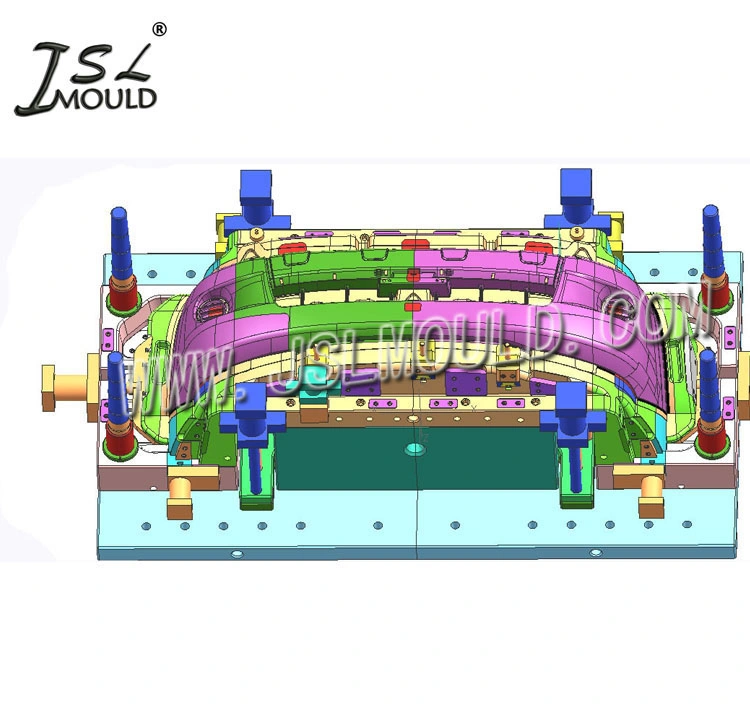

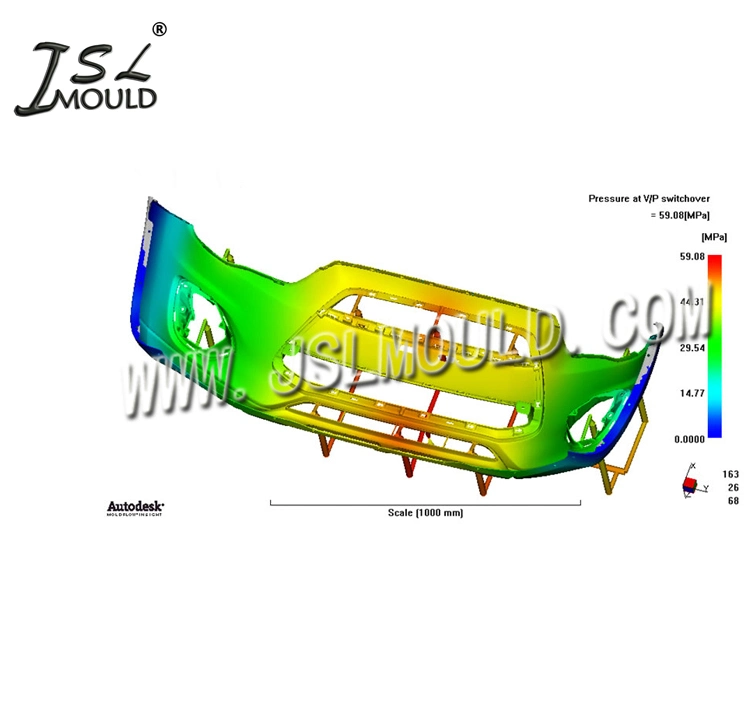

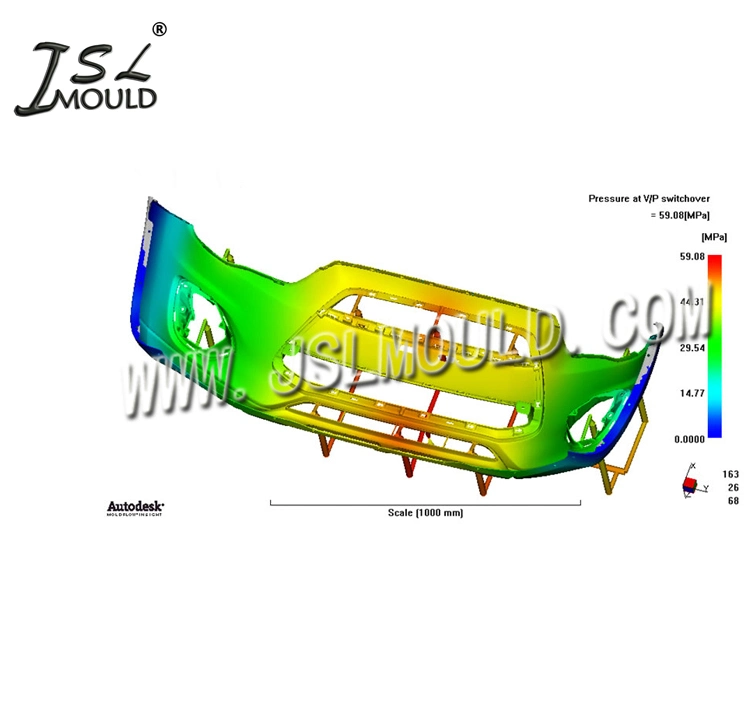

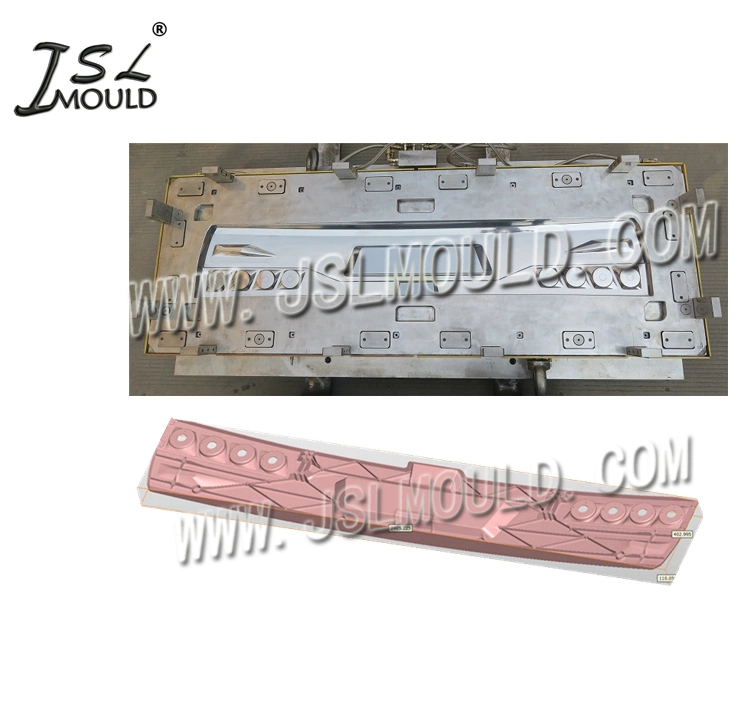

- design checking (part design, mould design, mould engineering drawing)

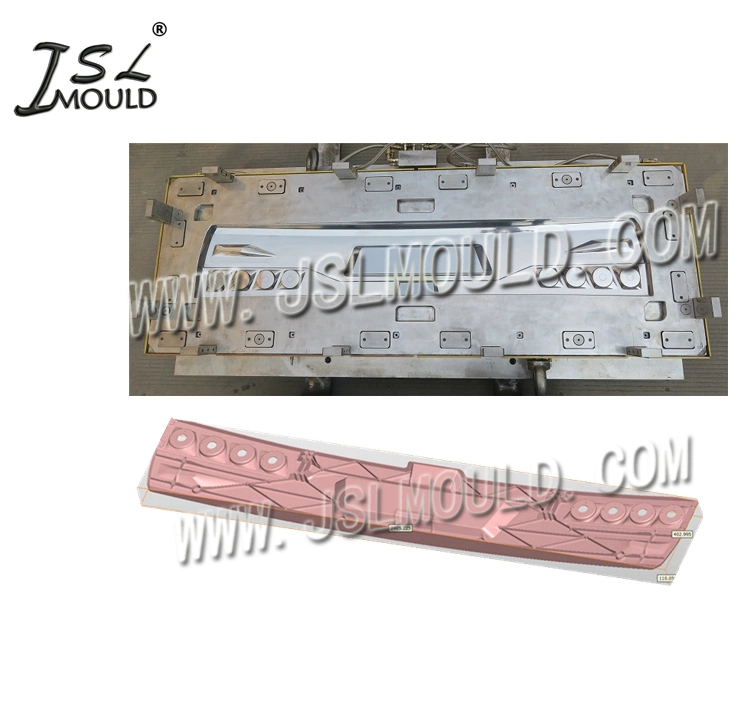

- checking each part of mould's size after machining, according to 2D drawing

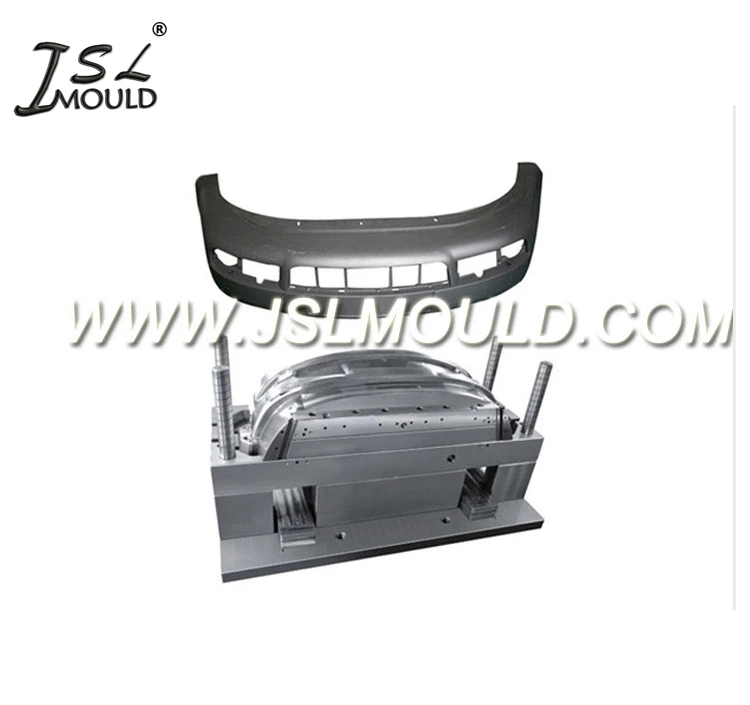

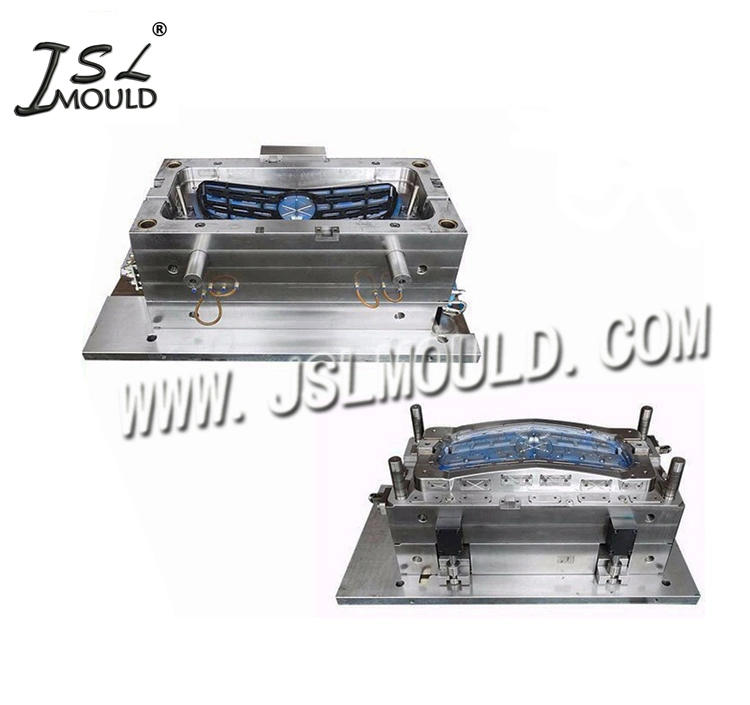

- mould testing(check mould running condition)

3. Check with customer's requirement again before mould shipping.

1. Provide 3D design

2. Mould Steel/hardness:718

3. OEM service

4. Mould life: 5 000, 000shotsJSL Mould Quality Control

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking(Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- checking each part of mould's size after machining, according to 2D drawing

- mould testing(check mould running condition)

3. Check with customer's requirement again before mould shipping.

Product Name | Professional Making High Quality Plastic Car Bumper mold |

| Product material | PP |

| Core&Cavity Steel | p20/718/2738 |

| Steel hardness: | HRC35-38 |

| Mould Standard | DME,HASCO,etc |

| Cavity Number | single |

| Injection System | Valve gate |

| Ejector System | Ejector pin |

| Cycle Time | 80-100S |

| Tooling lead time | 70DAYS |

| Mould life | 5000,000SHOTS |

| Quality assurance | ISO9001 |

| Specification | According to client's requirements |

| Our Advantage | 1.High quality |

| 2.Reasonable price | |

| 3.On time delivery | |

| 4.Good After-sale service | |

| 5.Strict quality control | |

| 6.All the mould are automotic. | |

| Offer you | In-time response on letters, telephone calls or fax |

| In-time supply the quotation and mould designs | |

| In-time communication on the technical points | |

| In-time sending pictures for the mould machining progress and mould finishing schedule | |

| In-time mould test and sample delivery | |

| In-time mould delivery. | |

auto bumper mold | |

| 1.Samples/Drawing &Requirement from you | |

| 2.Mould design:we will Communicate&Exchange the opinion with you after you place order. | |

| 3.Material Purchase:Steel cutting and Mould base tooling. | |

| 4.Assembling. | |

| 5.Inspection of mould : following and controlling the tooling processing. | |

| 6.Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you! | |

| 7.Your instruction &confirmation for shipment. | |

| 8.Ready made mould before packing. | |

| For more information please contact us. | |