One Step Injection Stretch Blow Molding Machine for 8 Cavity PC Bulb Shell

1. What is one step injection stretch blow molding machine (ISBM)?

--One step injecton stretch blow molding machine also known as singe stage injecton stretch blow molding machine is an integrated plastic bottle making machine, combined the function of preform injection, blow and stretch and ejecton together. It has the dual function of injection and pull blow and injection blow.

--Put the temperature adjustment and preform molding in the same time, thus no more reheating needed to complete a high speed molding. With the preform molding keeping heat to blow, it cuts the cost of reheat and shortens the cooling time.

2. Benefits of this single step injection stretch blow molding machine: high performance, effective and energy saving

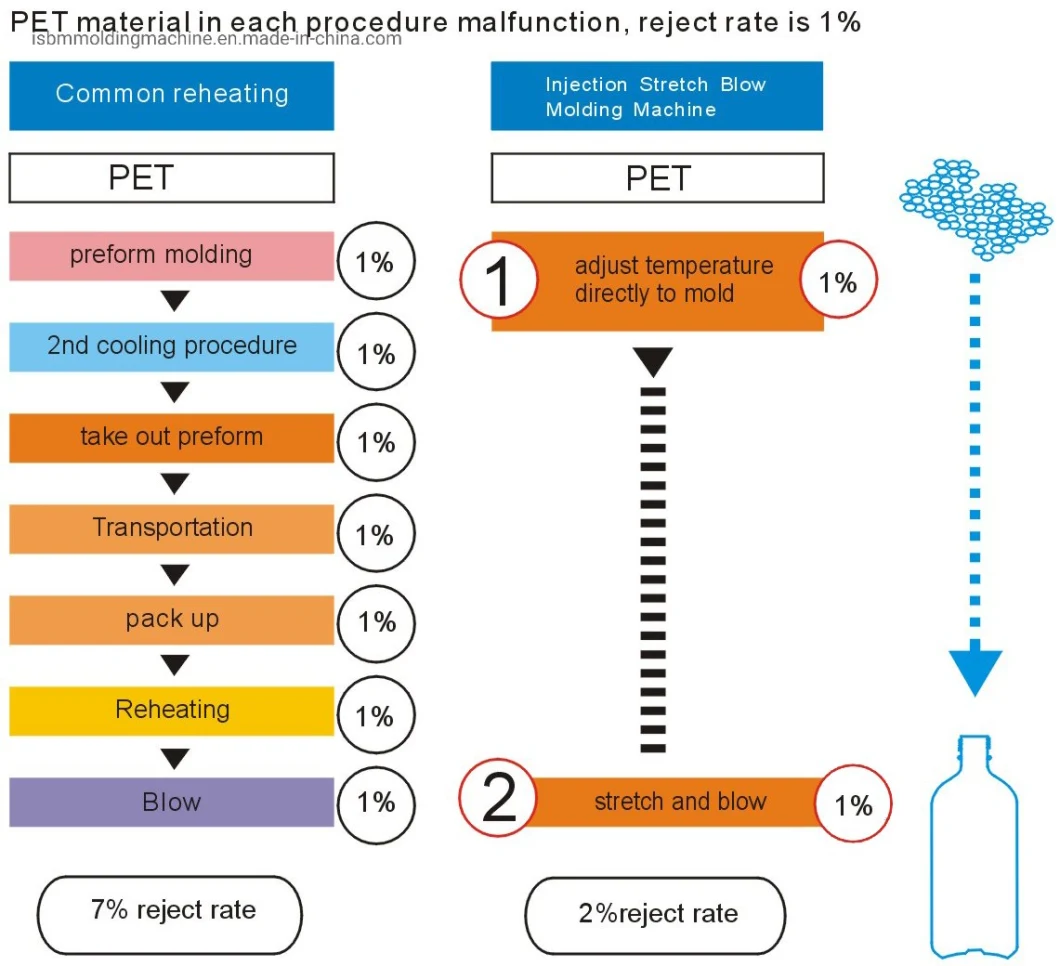

--One step preforming injection stretch blow molding machine VS traditional molding machine or two-step blow molding machine

- The whole process including mould injection, stretch blowing and off-molding can be finished. within one step, which means more energy efficiency and high quality for product.

- No reheat needed, it can perform the higher speed and more efficient and energy saving.

- Adopted PID control achieves precise and steady temperature for the material barrel and hot runner.

- Products from this injection stretch blow molding machine don't contain any flash, sprue, and much less disfigurement. It can present the perfect looking mouth, bottom and wedding line as well as the better transparence and high rigidity.

- Products are thinner and have better uniformity than those from both traditonal blow molding machine and two step blow molding machine. And 50% raw material can be saved.

- Servo moto driving wheel did a better job of avoiding products from pollution by hydraulic oil.

- Full automatic control, easy operation. No human intervention during the whole manufacturing process.

- Less transmission and working procedure save the products from damp and pollution so the hygienic requirement especially for food grade containers is well guaranteed.

- Can use recycling material and combined with the optimized and improved procedures, it achieves the best efficiency and cost.

- Integrated machine of compact structure, easy to maintain and takes less occupation area.

- Applicable to more shapes

--Injection blowing molding is the without-core dual direction stretch blowing measure, which is suitable for

PET, High transparent PP, PCTG, PETG, SAN, PC, PMMA, PS, Tritan (BPA Free)

--Widely used for manufacturing bottles for pharmaceutical, healthcare, food, beverages, cosmetics, lampshade and other applications.

1. Food and beverage bottles such as jar, can, tin, kettle, cruet etc.

2. Cosmetic and detergent bottles such as hand washing liquid bottle, shower gel bottle, perfume bottle etc.

3. Baby feeding bottle and sports bottle such as student bottle, vacuum bottle, juice bottle, baby feeding bottle etc.

4. Pharmacy bottle such as medicine bottle, eyedropper bottle, oral liquid bottle etc.

5. PC bottle and wine goblet such as water bottle, juice jug, beer jug, milky tea jug, wine jug etc.

6. Lamshade, lamp chimney, LED bulb housing, big safety bulb housing, irregular bulb housing Φ30-Φ80, Φ80-Φ300, lotus bulb housing etc.

7. Jerry cans, other irregular plastic bottles and irregular plastic containers etc.

4. Why us?

--We are the first to manufacture one forming molding machine in China and obtained a number of technical patents. On basis of digestion and absorption of overseas advanced technology of injection blow molding machine, we analyzed and made significant improvements.

--The best cost efficiency provides the best choice for inside empty molding partners.

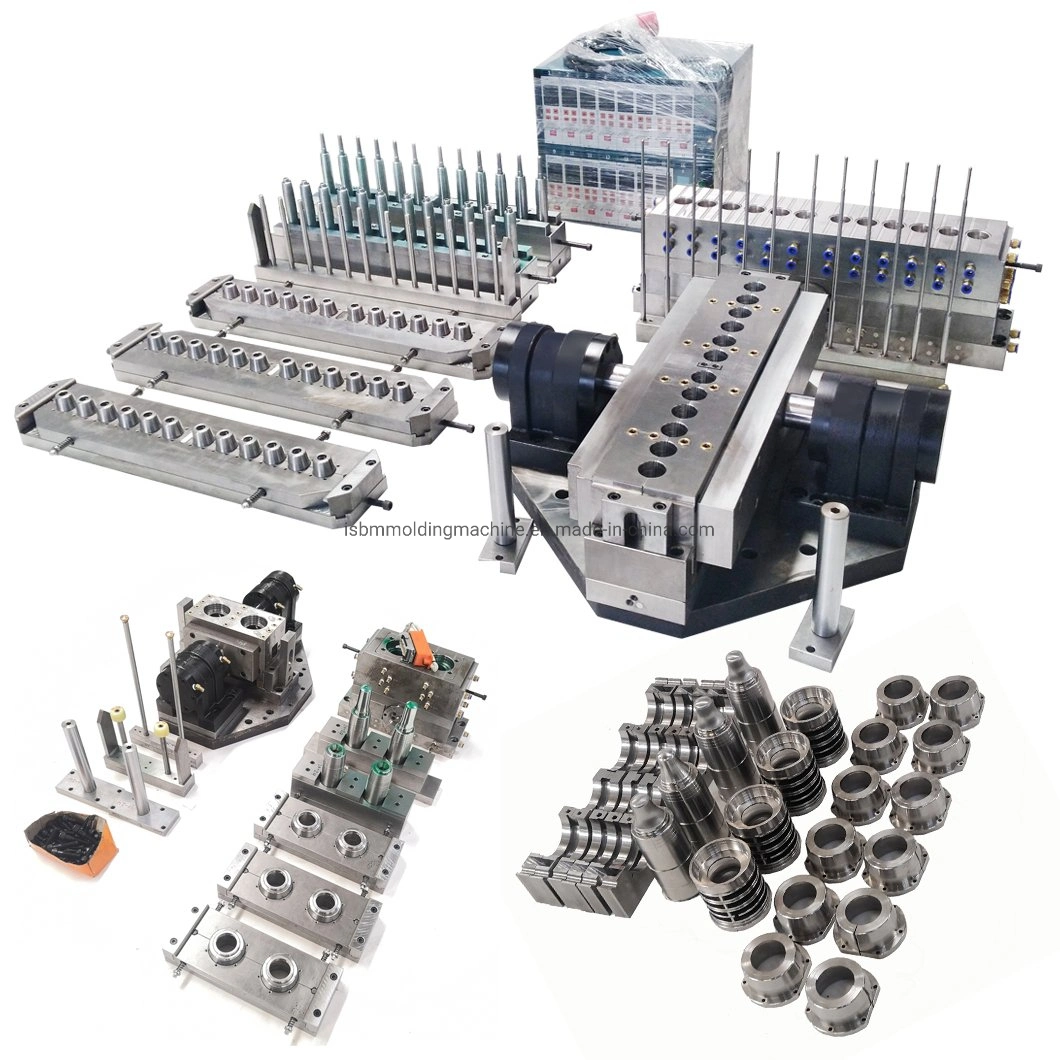

--Injection: Hot runner and temperature control device are standard configuration.

Only need to change the mold to make a new product.

Blow: Hydraulic mold clamping, core insert, blow and bottom molding are standard configuration.

Product release: Ejector is a standard device.

This design saves customers' tremendous amount of time and money in moulding.

5. Workshop Gallery

You will find more reasons for working with us.